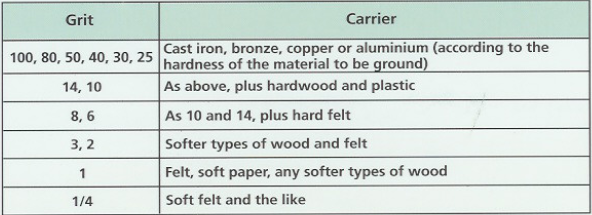

|

In

general the paste

carrier must be

softer than the

material to be

ground and must

offer sufficient

resistance to the

grinding pressure.

Diaspeed (diamond

polishing paste)

Diaspeed diamond

polishing pastes are

supplied in two

types:

Diaspeed-A (water

soluble)

This diamond paste,

with very high

adhesion is most

suitable for use at

higher rotational

speeds. Before

spreading, the paste

requires to be

thinned down with

water or solvents

such as carbon

tetrachloride or

trichloorethylene.

Diaspeed-C (soluble

in oil)

This diamond paste,

with less adhesion

than diaspeed-A, is

capable of being

very finely spread.

The paste is soluble

in oil (e.g. olive

oil).

Diapeed-C is

particularly suited

for hand polishing

or for machine

polishing with a to

and fro movement.

This paste may also

be thinned down with

solvents listed

under Diaspeed-A.

Both types can be

supplied in normal

and highly

concentrated

versions.

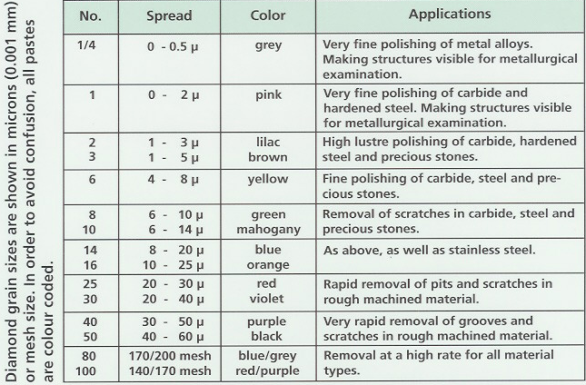

Diamond Grit

Size

Recommended sequence

of operation for

grinding and

polishing:

- Carbide 30-14-3 or

30-8-1

- Hardened steel

40-14-1/4 or

30-8-1/4

- Cast iron, non

ferrous metals,

glass and plastics

8-3-1/4 or 8-1-1/4 |