| |

|

|

|

|

|

|

|

IR Optics |

|

|

|

|

|

|

|

Attenuated Total

Reflection (ATR)

elements

The inherent

strength, wide

spectral

transparency and

chemical resistance

combination of

diamond makes it an

ideal crystal for

ATR applications.

Other ATR crystal

such as ZnSe or Ge

can be scratched or

corroded with some

materials under

test, however

diamond is

significantly more

resistant to this

effect. Diamond can

be configured into

planar or complex

geometric shapes for

ATR applications.

The configuration of

the ATR element and

the optical light

path will determine

what diamond type is

best suited for the

application. Both

natural and

synthetic diamond

types can be used. A

further option to

stand alone crystal

is mounting the

crystal to a

suitable frame or

fixture.

Windows for process

control

In situ process

monitoring has been

shown to be the most

effective way to

ensure that a final

product meets or

exceeds

specification. For

many aggressive

chemical processes,

viewing the process

is limited due to

temperature and

pressure of the

environment. Both

natural and

synthetic diamond (CVD)

can overcome many of

these impediments. A

planar piece of

diamond is typically

attached to a metal

frame creating a

component that can

be attached to a

process line. The

diamond window

assembly can be

engineered and

specified to

withstand extreme

conditions. Certain

processes may not be

extreme, but can

still utilize

diamond for its

chemical inertness

and durability.

Extended lifetime of

a view port may lead

to a benefit of less

maintenance and down

time providing

valuable cost

savings.

|

Type IIA IR window

for process

inspections |

CVD diamond windows

in an IR

transmission cell |

|

Synchrotron windows

A CVD diamond window

has been

incorporated into a

titanium flange. The

window assembly has

been designed for

use in infrared

beamlines. To obtain

a flat spectra, a

wedge of 1° is

induced over the

thickness of the

diamond window

reducing possible

interference fringes

in the far infrared.

The standard flange

is available for 2

window sizes, 15.0

and 20.0 mm in

diameter with a

clear aperture of

10.0 and 15.0 mm

respectively. The

assemblies are rated

to 1 bar pressure

differential,

bakeable to 200° C

and are leak tight

to 2 x 10-10 mbar

l/s.

|

|

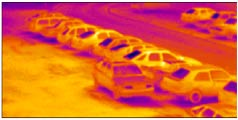

Thermal imaging

windows

Diamond has

exceptional

transmission

characteristics in

the 8-14 µm

wavelengths. A

diamond window

produced from either

natural or synthetic

diamond can be

processed to achieve

high flatness and

low roughness that

reduces distortion

in the transmitted

wavefront. The high

thermal conductivity

of diamond may also

be an advantage in

novel thermal window

applications.

|

Thermal image

through a high

quality CVD diamond

planar window. |

|

|

|

|

|